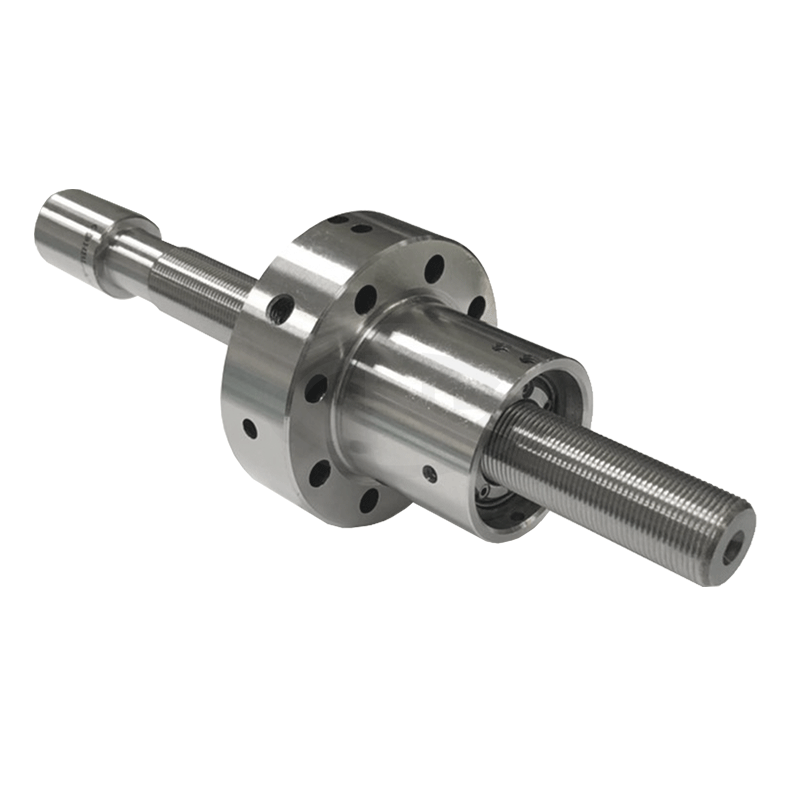

Precision and Customizability of Planetary Roller Screw Drive Systems for Various Industrial Applications

Planetary roller screw drive systems are an effective solution for converting rotary motion into linear motion with precision. Leveraging years of experience and profound expertise in screw engineering design, we have developed a product line that meets various requirements. Whether it's the highest linear speed, maximum rated load, or minimum structure height, the Chuan Hong precision product line offers the best solutions.

Our products include ground-grade and turned-grade planetary roller screws, which are optimized and designed for high-load and high-speed use in adverse environments. Compared with ball screws, planetary roller screws are better designed and have a more efficient circulation design.

Custom screws can be designed according to drawings, and nuts can be customized according to specific requirements. With the addition of sensors, real-time monitoring and predictive maintenance can be achieved.

These systems are suitable for use in automation equipment, medical-grade industry, precision machine tools, and special industrial machinery.

-

Standard Series

Advantages and Comparison of Planetary Roller Screws and Ball Screws for Linear Motion Control in Automated Equipment

Planetary roller screws are a popular choice for linear contact load transmission in automated equipment due to their various advantages. Their precision, repeatability, low noise, and reliability make them a desirable alternative to ball screws. Unlike ball screws, planetary roller screws avoid the issue of micro-vibration or noise generated during ball motion and the problem of different friction coefficients in forward and reverse rotation when carrying axial thrust. These screws also use precision matching of threads to allow rollers to roll in the thread groove, achieving linear motion control and high positioning accuracy.

Furthermore, planetary roller screws have a long life and high load capacity, making them ideal for use in automated equipment such as machine tools, robots, printing machines, and injection molding machines. In comparison to ball screws, they offer more benefits and are a better fit for linear motion control in such applications.

Series Overview -

Heavy Load Series

Customization and Versatility of Planetary Roller Screws for Diverse Industrial Applications

Planetary roller screws are high-precision and high-load transmission components that offer numerous advantages over ball screws, including precise positioning, high load capacity, and self- lubrication. These features make them ideal for precision industry positioning and measurement systems. Additionally, the contact area between the roller and the thread groove is large, giving planetary roller screws exceptional load-bearing capacity for high-load, high-speed, and high- acceleration motion control.

One of the key benefits of planetary roller screws is their customization and versatility. These components can be designed and manufactured to meet the specific needs and requirements of different industrial applications. This means that they can be tailored to meet the demands of industries such as aerospace, automotive, and robotics, among others. Planetary roller screws can also be customized to meet unique application scenarios and requirements, making them an attractive option for many different customers.

Another advantage of planetary roller screws is their low maintenance costs. Unlike ball screws, planetary roller screws do not require additional lubrication, reducing the need for maintenance and lowering costs over the lifetime of the component. With their high precision, load capacity, and customization options, planetary roller screws are an essential component in many industrial applications.

Series Overview